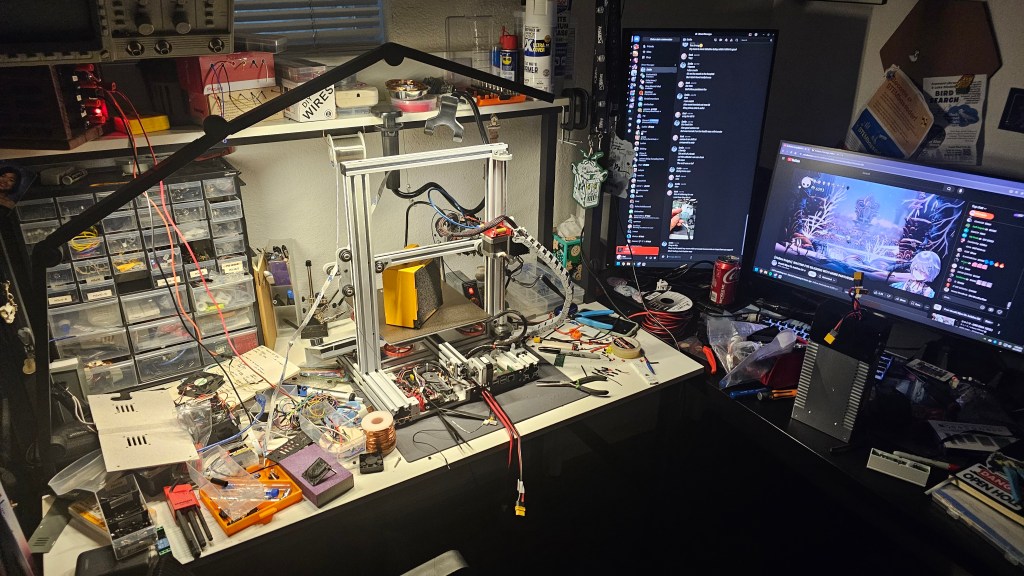

Since 2020, I have been stuck with the OG Ender 3 as my 3D printing workhorse. A lot of modifications went into it to make it reliable.

New BTT control board (twice from shorts), new hotend assembly, PEI bed and springs, etc. Relatively unchanged from 2-3 years ago.

So much so that I probably spent more on it than just to buy a brand new printer. But that’s also the reality of Ender 3 mods

Microcenter just recently opened in the Bay Area and of course I had to go check it out. I used to like going to Fry’s Electronic in Fremont as a kid and staring at the old computer games, amongst the interesting decorations and stuff. I think it had a tesla coil?? I also remember buying my first gaming PC there, an Alienware x51.

Anyways, Microcenter filled up a nice hardware nerd location that the bay area really needed after Fry’s closure. I was already settled on computer upgrades for the next couple of years but my main focus was the 3D printers and maker supplies.

Surprisingly, Microcenter held quite a collection of Adafruit module. Nothing that really stood out to me as instant buy and I already had a few waiting to be used in projects.

Towards the back held all the 3D printers. I have been thinking for a long time of upgrading my Ender 3 and buying a backup printer while I do modifications again, especially the hot end assembly that was wiggling a little. I remember having to replace my printer’s hardware with parts printed on the Ender 3. That was a awful experience having to reassemble it every time a part wasn’t correct.

I was interested in the Bambu A1 Mini. Cheap and should work out the box. Small but for my use case as backup, not a big concern. However, I have a personal disagreement with using Bambu printers and how enclosed their environment is. I have heard the comparison that Bambu is becoming the Apple of 3D printing and while its great for most users, I strongly support open-source hardware and machines that you can freely repair and modify after buying for life.

But then a sign from the heaven appeared. Voron kits.

The Voron 2.4 printer was my ultimate dream printer and a obvious jump from experience modding Ender 3s. But it was expensive, around 1000-1500$ estimated when sourcing parts. Something I reserved as a reward for a high-paying job.

After a bit of pacing and talking my thoughts out with my gf about how a Voron is not a poor financial decision and that it is absolutely necessary for my survival to buy it, I walked out the store with 8ish boxes.

The Microcenter kits are split up by part categories of frame, electronics, pre-made cables, fasteners, etc. Typically, people would buy the LDO kits pricing for a little under $2000. So that fact I got everything for 900 is really good in my opinion, even with the knowledge that parts inside the kit could be wrong or missing.

After getting home, I started to inventory all the kits and reference the Voron generated BOM to see if the kits aren’t a scam. For the most part, every part is there with a little extra fasteners. The cables are unknown but that part of the kit is cheap so any missing or incorrect connectors aren’t a concern for me.

Fasteners was the best steal because they provide just the right amount for the kit. Sourcing hardware cheaply would result in buying bulk kits, which was not the end of the world for a maker who still uses them for other projects, but could be a selling point for someone penny-pinching. I did find missing extra in one M5 bolt pack that I had to order. If you wanted to source everything yourself, best alternative would be to buy a M3 and M5 bulk variety kit alongside the other t-slot nuts and heat inserts.

I ordered KVP ABS because I fell in love with the British Racing Green color. I guess I’ll be printing parts for the Voron on my Ender 3 so that the Voron can print parts for the Ender 3.

I will document the assembly in a new post and any quality issues with the kit. I can’t wait to get it up and running!

But first, I had to fix my Ender 3 up with Octoprint.

Leave a comment