This month marked the start of spring quarter and the 2nd part of senior design, where teams are tasked with making a physical prototype for the designs proposed and documented last quarter.

My team had landed upon a geared mechanism for a 2-DOF solar array system, rotating by a internal planetary gear and a central shaft. All components were to be 3D printed and I had proposed to use my 3D printer, not because it can beat the strength and quality of the machine shop’s nylon SLS printer but ease of rapid iterations.

A couple other teams also had personal printers and that rapid prototyping process really improved how successful each design turned out.

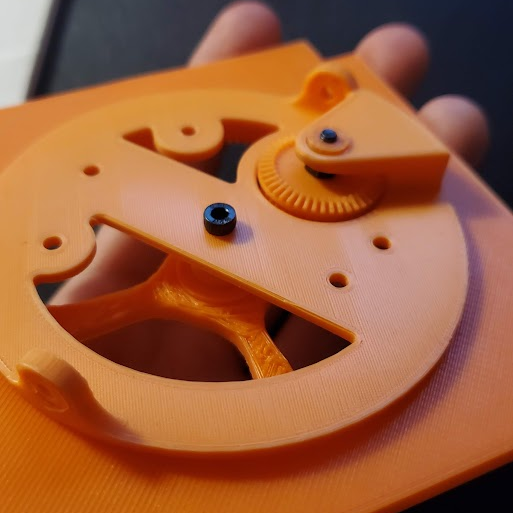

The 3D model had been drafted since last quarter’s report but I took extra time to refine it for 3D printing. I was significantly faster at creating 3D models compared to my teammates and since I really really wanted a working prototype, I understood how much expedited progress was needed. So in a couple nights, several iterations of the assembly was modeled and printed, including the gears which is generally not recommended.

Although gear CADs are easily obtained off McMaster-Carr which I usually pull from, this assembly requires extremely tiny gears common in RC cars. As much as I’d like to use RC car gears off the shelf and was proposed by my team, the specs of the gear are not documented at all, making it impossible to design around without buying. And I was still extremely stingy about spending money.

Luckily, there are gear profile generator plugins you can download to make special gears like the bevel gears used to spin the entire array. Plus, you can make herringbone gears that work a lot better for aligning 3D printed parts.

My Ender 3 loves Hatchbox PLA. Everything else I need to fine tune way more but the way I tuned my Hatchbox PLA has it coming out clean and resin-like, especially with ironing on. However, my FDM printer can only achieve so much resolution so the gears experience slight backlash and slip.

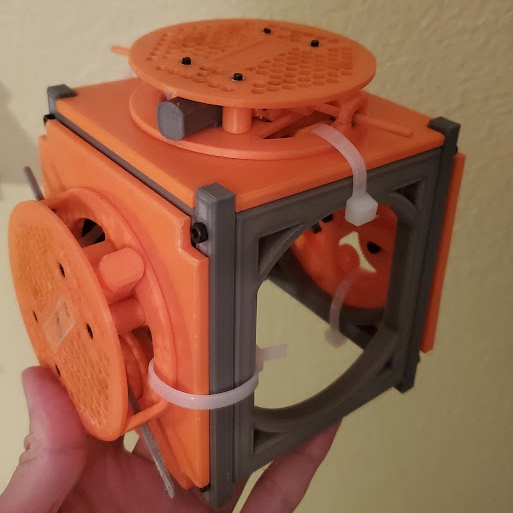

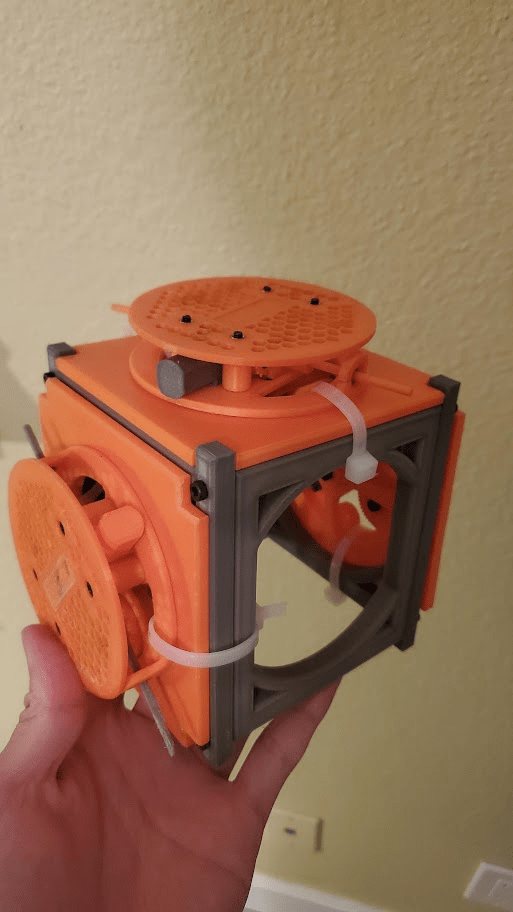

I really liked the open clearances I made for the wires to pass through, inspired by the way outrunner motors look.

Even without proper bearings (3d printed mock bearings), the assembly moved smoothly and I presented it to the rest of my team for further steps and design changes.

Cut to May, I had made 3 working concepts, complete with motor stand-ins and a protective cover (added visual flair of holes as a real-world design would be closed and sealed from radiation and space debris impact.

Here’s all three attached to a CubeSAT mock model for size comparison

Oh yea I bought a new plant from UCR’s botanical garden, Hatiora salicornioides, or drunkard’s dream.

[October 2025] Still my favorite plant and thriving. Haven’t seen these yellow flowers appeared since and I’ll probably need to stress the plant a bit next spring. It’s getting very spoiled

I was definitely way more invested in making a quality project. Oddly senioritis did not hit me like other classmates, who were also busy with other classes, projects, or research.

Leave a comment